| Author / Post |

|

ghethco

ghethco

Lifetime Site Supporter

|

Joined: March/04/2005

United States United States

Posts: 1835

IP Logged

|

| Posted: October/09/2008 at 11:54am |

Quote

|

|

Hi guys,

I've taken on another prop project for the Ho 229 documentary. Yes, you read it right, a 1:1 scale cockpit mockup. It's to be used as a prop. Exactly how it is to be filmed, I'm not sure yet. I'm going to try to make it as realistic looking as possible.

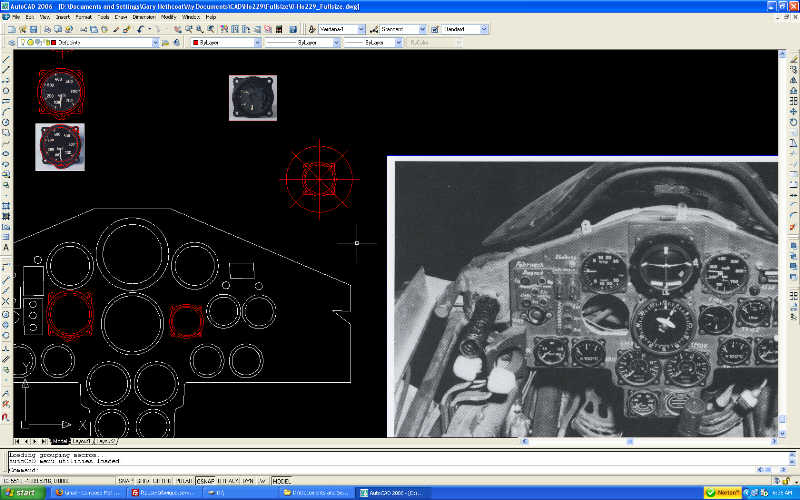

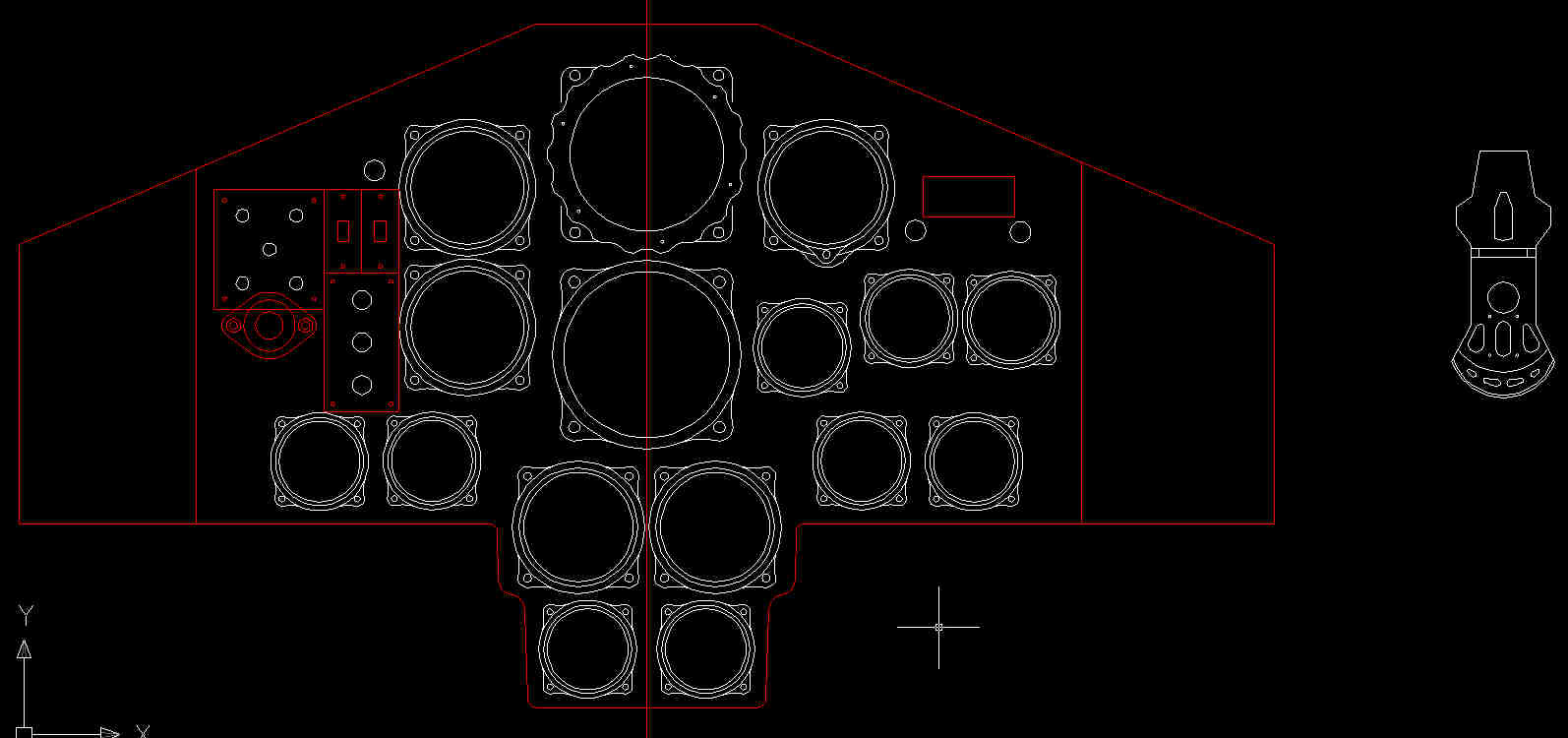

Here are a few shots of the CAD workspace. Not quite sure how this will look munged down to 80K. Should give you an idea though.

My current plan is as follows. Tubular framework made out of ABS and PVC pipe as used for plumbing. Instrument panel & bezels laser cut from ply. Instrument faces will be photo reproductions with acrylic over top.

The seat will be made per the original, welded steel tubing! This is going to be the challenging part since I've never done any welding before. The problem is, I *know* people are going to want to sit in it, and no other material would be strong enough to take the abuse. The stick and other details will be either plywood, PVC or more steel tubing depending on how the welding goes.

I've got my hands on an acetylene welding/cutting outfit. A bit scary but also exciting!!! Ever seen the Beevis & Butthead show where Beevis goes around saying "Fire. Fire." when he's playing with matches? :-) Just have to figure out how to get the job done without burning myself or the house down :-)

More later.

Gary

__________________

Gary Hethcoat

Building: 43" Heinkel He 100

Wings on the Web

|

| Back to Top Printer Friendly Version Profile

Search

Web

|

| |

|

BillF

BillF

Basic Member

|

Joined: October/16/2004

United States United States

Posts: 1303

IP Logged

|

| Posted: October/09/2008 at 12:54pm |

Quote

|

|

This is SOOOO cool.

I cannot wait to see it.

I've always wanted to do something similar for a FW 190 or Bf 109 cockpit for my flight simulators.

|

| Back to Top Printer Friendly Version Profile

Search

Web

|

| |

|

boomslang13

boomslang13

Basic Member

|

Joined: June/23/2006

Canada Canada

Posts: 764

IP Logged

|

| Posted: October/09/2008 at 1:00pm |

Quote

|

|

I suggest, if you have never done it before, that it would be faster cheaper and better if you get a pro to weld the tube for you. Tube welds are not the easiest to do. A motorcycle shop in your area can probaly steer you in the right direction

__________________

Even Murpy's law doesn't work ALL the time!

|

| Back to Top Printer Friendly Version Profile

Search

|

| |

|

dhal22

dhal22

Lifetime Site Supporter

|

Joined: November/19/2006

United States United States

Posts: 1172

IP Logged

|

| Posted: October/09/2008 at 8:49pm |

Quote

|

|

or you could take the parts to a weld shop and have them weld it up. or make a jig to assemble it it and bring the entire assembled unwelded package to them and let them have at it. btw, are you talking about schedule 20 or 40 steel pipe? if so then a conventional welder or wire welder can do the work. if you are going to use stainless or aluminum to make it lighter you are definitely going to need a pro.

david

|

| Back to Top Printer Friendly Version Profile

Search

|

| |

|

ghethco

ghethco

Lifetime Site Supporter

|

Joined: March/04/2005

United States United States

Posts: 1835

IP Logged

|

| Posted: October/10/2008 at 8:48am |

Quote

|

|

Hi guys,

Well, I'm going to give the welding a shot. I don't think we can afford a pro. I'm only getting reimbursed for materials on this one. I have some people I can get help from if I need it.

I'm not planning to use any exotic metals, just plain weldable mild steel. Weight isn't an issue since this isn't going to fly :-)

Just reading the safety information about fire and explosions is a little scary though, I have to admit!

Gary

__________________

Gary Hethcoat

Building: 43" Heinkel He 100

Wings on the Web

|

| Back to Top Printer Friendly Version Profile

Search

Web

|

| |

|

BillF

BillF

Basic Member

|

Joined: October/16/2004

United States United States

Posts: 1303

IP Logged

|

| Posted: October/10/2008 at 10:30am |

Quote

|

|

The only way to learn is to try.

I can't wait to see what you come up with.

You gotta admit though, sitting in the Ho-229 must have been interesting, jet engine on either side (you could actually reach out and touch the engines) and a retract right under your butt and the giant wheel behind you.

|

| Back to Top Printer Friendly Version Profile

Search

Web

|

| |

|

J_Whitney

J_Whitney

Moderator Group

|

Joined: November/10/2003

United States United States

Posts: 7527

IP Logged

|

| Posted: October/10/2008 at 3:25pm |

Quote

|

|

Gary - if you talk to Bob Freshwater or Don Rowlands at SACRC they may be able to help you - the club has a MIG welder.

__________________

Jeff

Castro Valley, CA

The essential paradox of our democracy is that our warriors fight and die for our right to dispute the cause for which they are fighting and dying.

Let me know if I can help

|

| Back to Top Printer Friendly Version Profile

Search

|

| |

|

ghethco

ghethco

Lifetime Site Supporter

|

Joined: March/04/2005

United States United States

Posts: 1835

IP Logged

|

| Posted: October/10/2008 at 7:52pm |

Quote

|

|

Hi guys,

Bill -- thanks for the encouragement!

Jeff -- thanks for the offer of the MIG welder. But -- check it out, my first weld!

OK, it's a bit sloppy, but it worked! I couldn't break it with a hammer.

I can do this!!!

Gary

__________________

Gary Hethcoat

Building: 43" Heinkel He 100

Wings on the Web

|

| Back to Top Printer Friendly Version Profile

Search

Web

|

| |

![]](/skins/text/forum_images/header-bg.gif)

![]](/skins/text/forum_images/header-bg.gif)